Electronic Fluorinated Liquid: The Invisible Guardian of the Tech Industry

— Unveiling the Key Material Behind Cutting-Edge Manufacturing

In today's era of rapid technological advancement, critical fields such as semiconductor chip fabrication, efficient cooling for data center servers, and the safety of new energy batteries all rely on a seemingly ordinary liquid that plays a vital role—electronic fluorinated liquid. Much like the "transparent bloodstream" of modern high-end manufacturing, it rarely makes headlines yet remains one of the core materials driving continuous upgrades in frontier industries like 5G communications, artificial intelligence, and new energy.

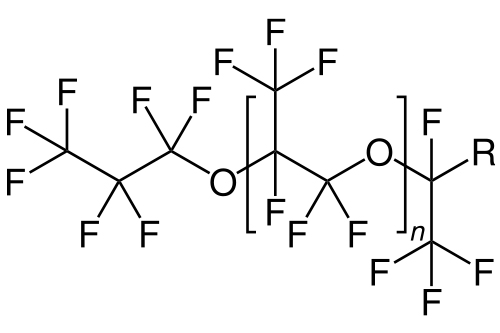

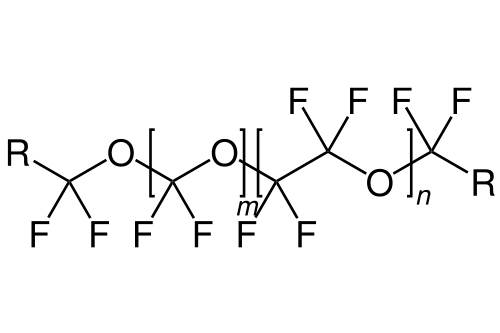

Electronic fluorinated liquid is a type of functional liquid material primarily composed of fluorocarbon compounds. In its molecular structure, hydrogen atoms are extensively replaced by fluorine atoms, forming exceptionally stable C–F bonds. This unique chemical structure endows the liquid with extraordinary chemical inertness, excellent electrical insulation, robust thermal stability, and outstanding heat dissipation capabilities. Its dielectric constant can be as low as 1.8–2.0 (for reference, air’s dielectric constant is 1), meaning it conducts almost no electricity. Moreover, its boiling point spans a wide temperature range—from 35°C to 275°C (and up to 290°C under special conditions)—allowing it to easily adapt to various extreme industrial environments.

Different types of perfluoropolyethers(PFPE)

|  |

| PFPE-K | PFPE-Z |

1. The “Essential Assistant” in Semiconductor Manufacturing

In chip production, electronic fluorinated liquid plays an indispensable role. It is used to clean nanoscale impurities from wafer surfaces, effectively preventing the corrosive effects that traditional solvents might inflict on delicate circuits. Furthermore, certain fluorinated liquids—with their high purity and low surface tension—are specially employed for wafer cleaning. By harnessing the Marangoni effect to remove residual moisture, they circumvent the safety issues associated with conventional isopropyl alcohol (IPA), thereby ensuring precision in high-stakes chip manufacturing processes.

2. The “Cooling Specialist” in Data Centers

Amid global efforts toward peak carbon emissions and carbon neutrality, governments are imposing increasingly strict regulations on data centers’ energy usage efficiency (PUE). According to the "Special Action Plan for the Green and Low-Carbon Development of Data Centers" jointly issued on July 3, 2024, by the National Development and Reform Commission and other agencies, newly built and upgraded large-scale data centers must achieve a PUE below 1.25 by the end of 2025, with national hub data center projects capped at 1.2.

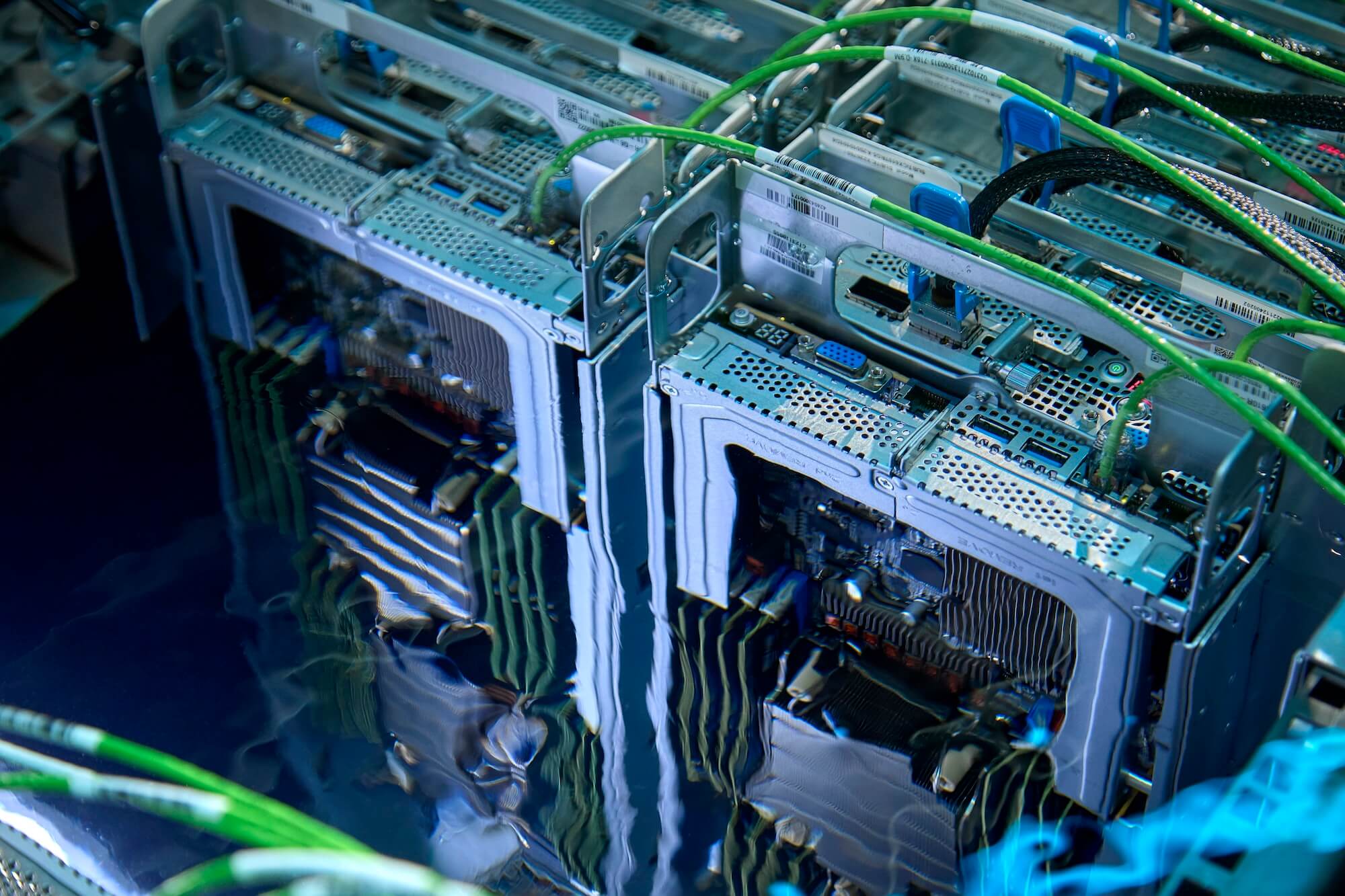

At the same time, the rapid growth of AI technology has led to an exponential increase in computing power demands. The widespread deployment of high-density GPU servers has caused a dramatic surge in energy consumption, posing significant challenges to meeting PUE targets. In this context, reducing the energy consumption of cooling systems becomes crucial. According to the ZTE Liquid Cooling Technology White Paper, cooling systems can account for more than 24% of a typical data center's energy use—the highest share among auxiliary systems. By adopting phase-change immersion liquid cooling technology, data centers can achieve PUE values between 1.15 and 1.05, realizing impressive energy savings. Here, electronic fluorinated liquid plays a key cooling role, enabling data centers to operate in a green and efficient manner.

Immersion liquid cooling servers

Immersion liquid cooling servers

3. The “Insulation Guardian” for High-Voltage Power Equipment

In high-voltage applications—such as ultra-high voltage transformers, new energy vehicle battery packs, and energy storage stations—fluorinated liquids serve as insulating and cooling media, ensuring long-term stable operation. For example, KEY-140, part of the KEY series from Zhongke Micro New Materials, boasts a boiling point of up to 275°C and a breakdown voltage exceeding 40 kV/mm. This means it remains stable even in high-temperature environments without decomposing or degrading, significantly reducing the risk of electrical faults like short circuits and ensuring the safe operation of high-voltage equipment.

The world's first submerged liquid-cooled energy storage power station - China Southern Power Grid Meizhou Baohu Energy Storage Power Station

4. The “Extreme Environment Adaptor” in Aerospace and Military Applications

Thanks to its unique physicochemical properties and robust tolerance to extreme temperatures (from –130°C to 275°C), electronic fluorinated liquid is widely used in cooling systems for fighter jet radars and satellite electronics. Public reports from NASA highlight that in the harsh environments encountered by space vehicles, fluorinated liquids demonstrate distinct advantages and high practical value. They provide solid support for the reliable operation of aerospace and military equipment under extreme conditions.

1. Exceptional Physicochemical Properties

- Chemical Inertness: Electronic fluorinated liquids barely react with common substances such as acids, bases, or metals. They have been certified by the U.S. Environmental Protection Agency (EPA), with an LD₅₀ (median lethal dose) exceeding 5000 mg/kg—essentially rendering them non-toxic. This stability ensures they remain uncontaminated and safe in complex applications.

- Superior Thermal Management: With a thermal conductivity of 0.06–0.12 W/(m·K)—significantly higher than air’s 0.026 W/(m·K)—these liquids greatly enhance heat dissipation. This effectively mitigates the heat buildup in electronic devices during operation, ensuring stable performance.

- Environmental Sustainability: New hydrofluoroether (HFE) based fluorinated liquids have an ozone depletion potential (ODP) of 0, fully complying with the Montreal Protocol. In an era of growing global environmental awareness, this makes them a promising, long-term solution.

2. A Rigid Demand Driven by Industrial Upgrades

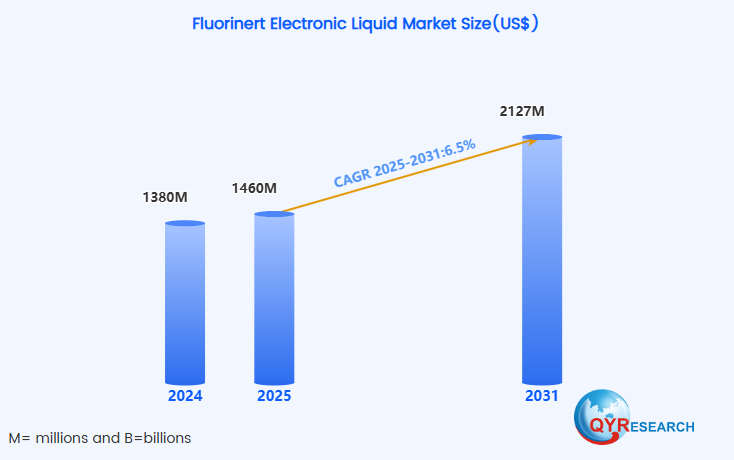

With the rollout of the U.S. CHIPS and Science Act and China’s 14th Five-Year Plan for electronic materials, self-reliance in the semiconductor supply chain and the greening of data centers have become unstoppable global trends. According to market research firm QYResearch, global sales of electronic fluorinated liquids reached USD 1.38 billion in 2024. Forecasts predict that this market will exceed USD 2 billion—reaching approximately USD 2.127 billion by 2031—with a compound annual growth rate (CAGR) of 6.5% from 2025 to 2031. This robust market trajectory underscores its indispensable role in industrial upgrades and further highlights its irreplaceable nature.

Image source:QRYesearch

For a long time, the core technology behind electronic fluorinated liquids was monopolized by international giants like 3M. However, in recent years, Chinese tech companies have vigorously accelerated their independent research and development, gradually breaking the foreign technology blockade and successfully overcoming this “choke point” challenge. For example, Zhongke Micro New Materials’ KEY series—comprising models such as KEY-114, KEY-117, KEY-118, and KEY-125—has not only met industry certifications but also achieved internationally advanced standards in critical metrics like purity, dielectric strength, thermal conductivity, boiling point, surface tension, and viscosity. Successfully applied in new energy, lithium batteries, AI data centers, and semiconductor manufacturing, these products have established an excellent reputation for domestically produced electronic fluorinated liquids, marking a substantive breakthrough in this key material field and paving the way for a competitive stance in the global market.

The value of electronic fluorinated liquid lies not only in its high technological barrier but also in its role as a bridge between materials science and advanced manufacturing. From the smartphones we use daily to the massive supercomputers in data centers; from battery cooling systems in new energy vehicles to the electronic protective devices on satellites soaring through space—this seemingly "invisible" liquid has become an indispensable enabler in the modern tech industry. Looking ahead, as domestic production accelerates, electronic fluorinated liquid is poised to play an even more significant role in high-end manufacturing, writing a brilliant new chapter in its legacy.

LATEST NEWS

- Conquering Wutong Peak, Forging the Spirit of Teamwork Zhongke Micro New Materials’ Autumn Team-Building Adventure Comes to a Triumphant Close 2025-11-02 22:49:03

- Zhongke Micro New Materials Recognized as a National High-Tech Enterprise, Driving the Localization of Fluorine-Based Materials 2025-03-19 17:51:28

- Electronic Fluorinated Liquid: The Invisible Guardian of the Tech Industry 2025-02-17 17:22:05

- Uniting Our Strengths to Shape a Shared Vision 2025-01-24 11:49:48

- Transforming digitalization and grasping the "digital" economy 2023-10-10 17:33:48

- Tightly tighten the "safety string" and firmly turn the "safety off" 2023-10-10 17:08:40

- On June 4, 2021, zhongkewei successfully passed iso9001:2015 quality management system certification. 2021-08-16 11:49:54

- On June 4, 2021, zhongkewei successfully passed the iso14001:2015 environmental management system certification. 2021-08-16 11:52:42

- Member of China fluorine silicon organic material industry association 2021-06-16 10:54:33

- Analyze the stainless steel antifingerprint oil 2021-06-16 11:32:08