Scan the QR-code to get technical consultation immediately

KEY-116 Electronic Fluorinated Liquid (Can Replace 3M Novec™ 7100)

Product Highlights

Wide range of thermal management applications | Low surface tension | Low kinematic viscosity |

Insulation | Wide material compatibility | Low toxicity |

Low Global Warming Potential (GWP) | Zero Ozone Depletion Potential (ODP) | No burning |

Not a volatile organic compound | Comply with RoHS environmental directive | Comply with REACH environmental directive |

Product Features

Stable Chemical Inertness: Does not corrode materials or react with them; no yellowing, decomposition by-products, or compatibility issues during long-term use.

Insulation Properties: Excellent dielectric constant and high insulation performance.

Low Surface Tension and Low Kinematic Viscosity: Superior wettability, strong solvency, enhanced thermal conduction efficiency, improved permeability, reduced adhesion to solid surfaces, optimized coating/spraying performance, and higher cleaning efficiency.

Residue-Free: Rapid drying with no residue or whitening marks post-evaporation.

Excellent Thermal Conductivity: Outstanding temperature control capabilities.

Cost Efficiency: High boiling point minimizes evaporation loss.

Safety & Environmental Compliance: Non-flammable (no ignition/flash point), no explosion/combustion risks; non-toxic, odorless, and free of carcinogens (no components listed by OSHA, IARC, or NTP). High permissible concentration (TWA).

Multiple Variants: Wide boiling point range and diverse options to meet varied requirements.

Industry Applications

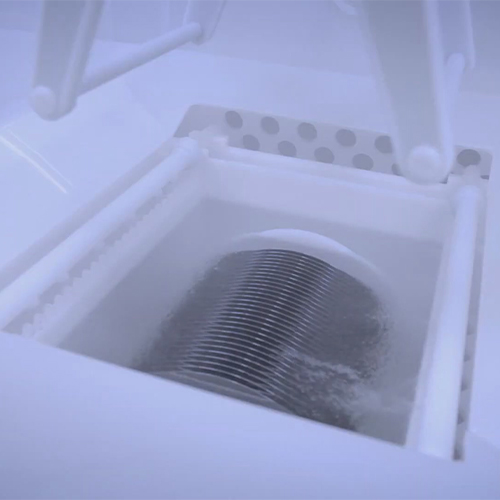

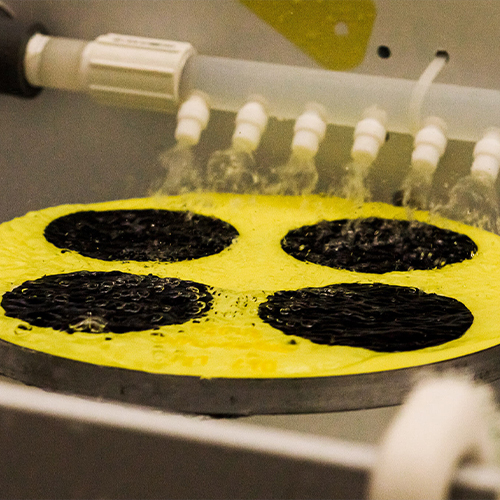

- Heat conduction and cooling media, heat dissipation media for computer servers, electronic components, power batteries, energy storage, etc.

- Semiconductor, chip manufacturing, packaging testing, laser etching.

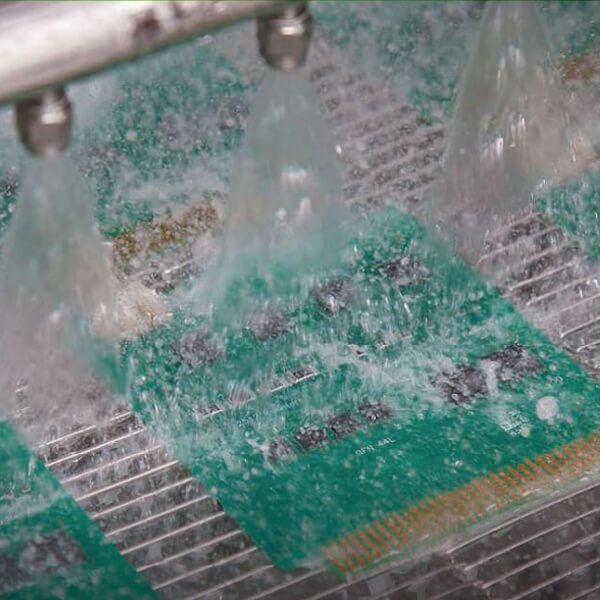

- Cleaning and maintenance of electronic, electrical and power equipment without power outages or stopping work.

- Provide insulation protection inside high-voltage equipment.

- Cooling and lubrication during milling and grinding.

- Precision cleaning, dehydration, leak detection, and testing of electronic components.

- Solvent diluents, lubricant diluents and other solvents for other purposes.

- Thermal shock test fluid.

Physical And Chemical Parameters

KEY-116

| Appearance | Colorless Transparent Liquid | Surface Tension | 13.6 dyn/cm | |

| Odor | Odorless | Thermal Conductivity | 0.069 W/m·K | |

| Content | ≥99% | Dielectric Strength | >25 kV | |

| Boiling Point | 65℃ | Dielectric Constant | 7.27 | |

| Pour Point | <-135℃ | Solubility of Water in Liquid | <10 ppm | |

| Kinematic Viscosity | 0.38 cSt | Flash Point | None | |

| Density | 1.50 g/ml | ODP | 0 | |

| Specific Heat | 0.28 cal/g ℃ | KB Value | - | |

| Refractive Index | 1.28 | GWP | Low | |

| Thermal Expansion Coefficient | 0.0011 cm³ /cm³ ℃ |

Notes:

1. Product properties are the characteristics at 25°C, excluding boiling point and freezing point.

2. 1 torr is equivalent to 1 mm mercury column pressure. One atmosphere is about 100,000 Pa, and it is equivalent to 760 mm mercury column pressure. So 1KPa is equivalent to 7.6 torr.

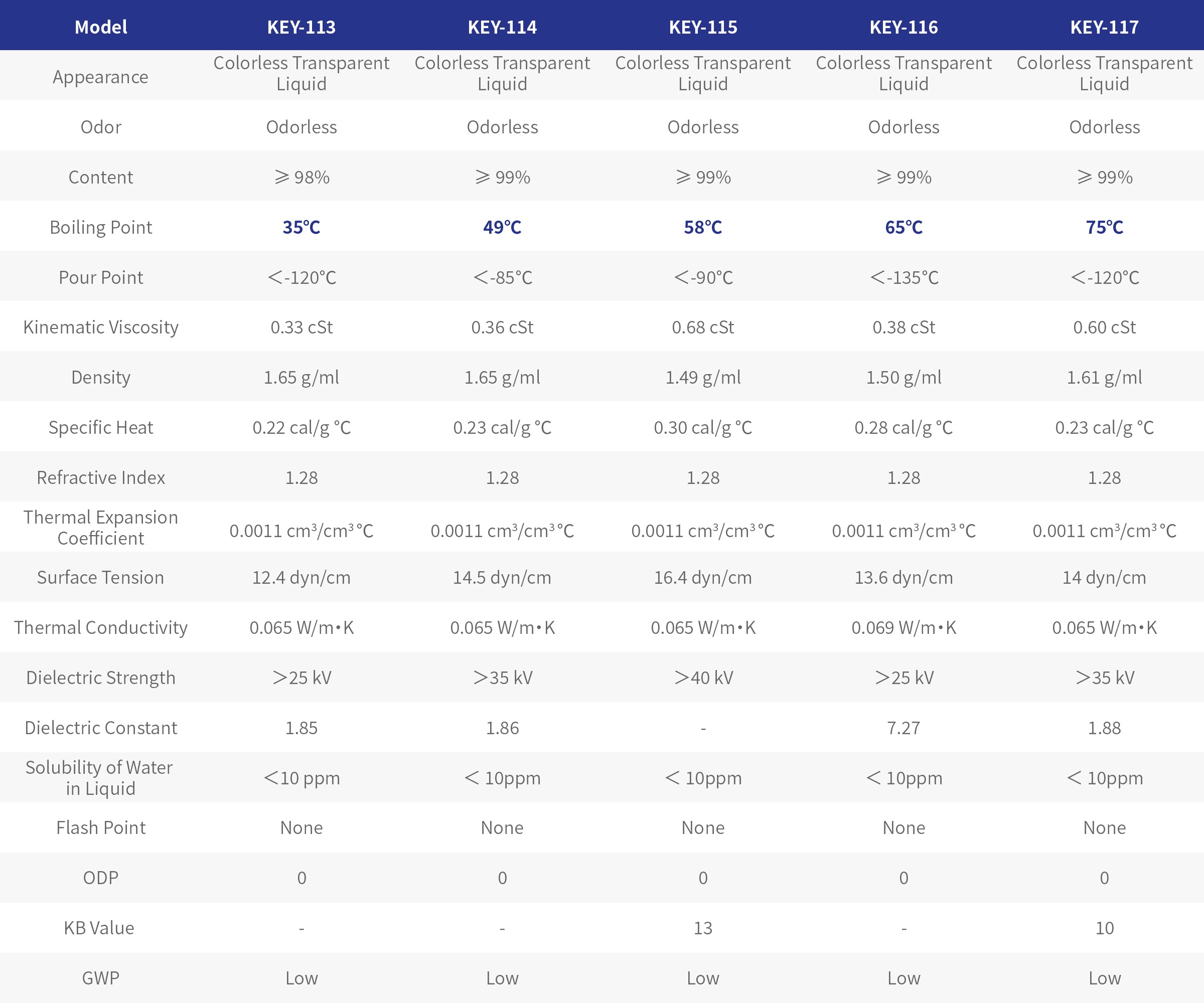

KEY Low Boiling Point Fluorinated Liquid (35℃~75℃) Detailed Parameter Comparison Table

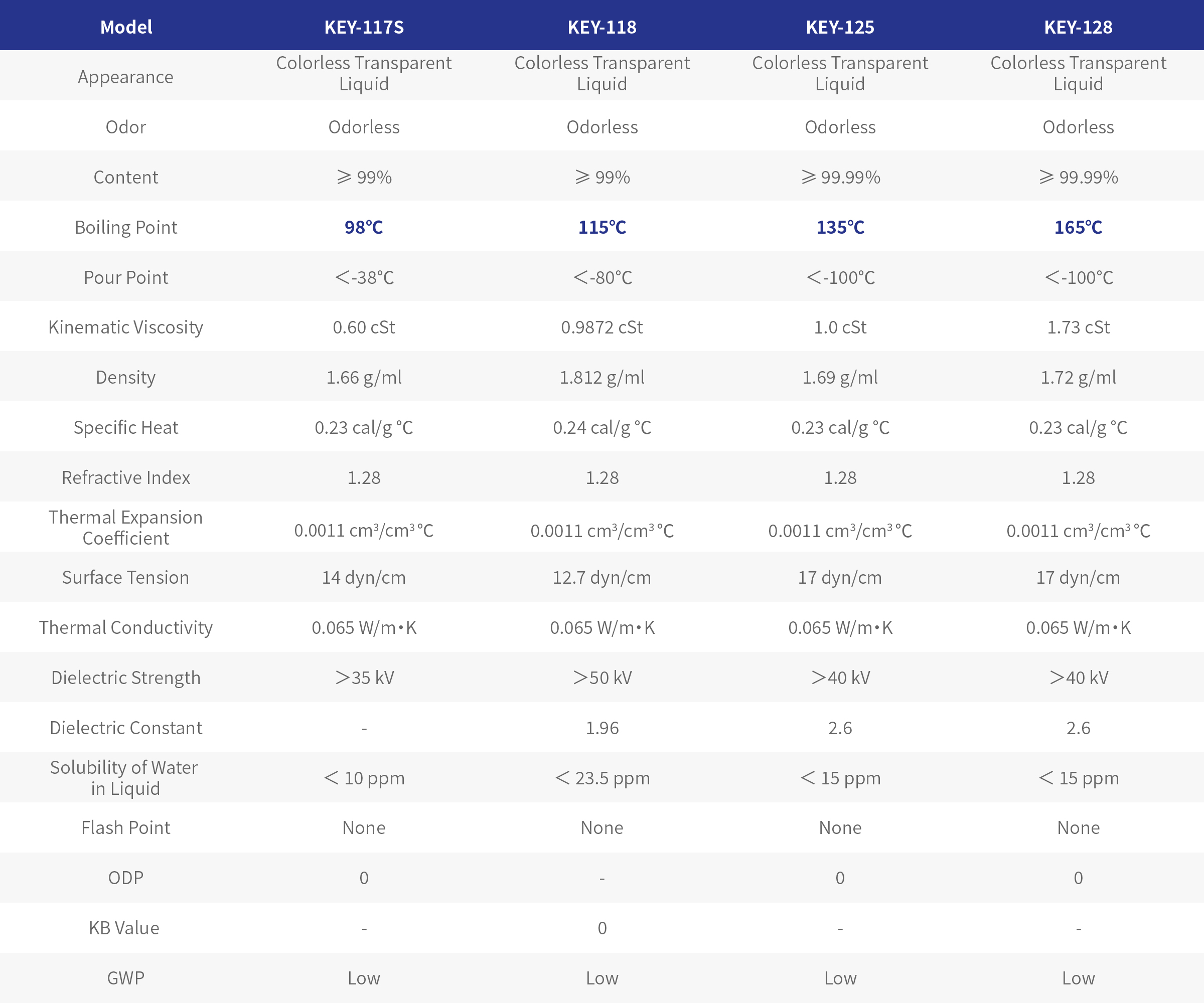

KEY Medium Boiling Point Fluorinated Liquid (98℃~165℃) Detailed Parameter Comparison Table

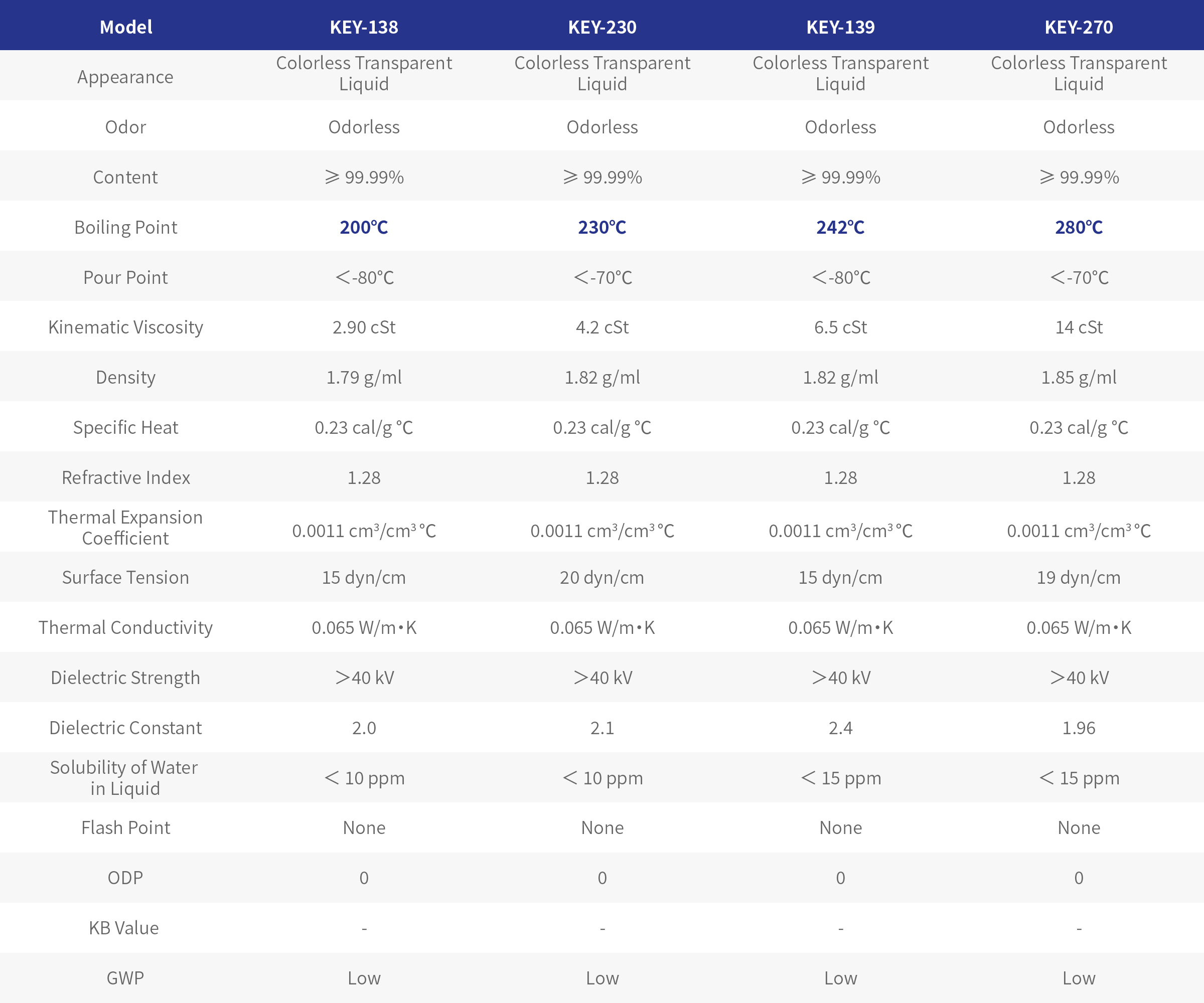

KEY High Boiling Point Fluorinated Liquid (200℃~280℃) Detailed Parameter Comparison Table

Storage and Transportation Requirements and Precautions

Transport as Non-hazardous and Non-corrosive Chemicals and Store at Room Temperature.

Pay Attention to Sealing and Avoid Direct Sunlight and High Temperatures.

The Warranty Period Is 24 Months in Sealed Condition.

Do Not Mix with Strong Acids, Strong Alkalis, And Reducing Substances.

It Is Recommended to Carry out a Compatibility Test Before Use.

Packing Specifications

|  |  |  |  |  |  |

| 5 KG | 10 KG | 15 KG | 20 KG | 25 KG | 50 KG | 100 KG |